Start up Medical Device companies

Lean Startup Implementation

A lot has been written about how Lean Startup methodology might help entrepreneurs build commercially successful products. In this article we provide a real-life example from one of our clients, which failed to develop a commercially successful product, and show how implementing Lean Startup methodology may decrease the likelihood of such failures.

1. The Problem

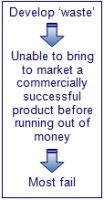

Over the last seven years, we provided consulting services to more than 150 different medical device startups. The sad truth is that most of them failed.

They failed because they did not manage to bring to market a commercially successful product before running out of money. Note they succeeded in bringing to market all sorts of very sophisticated products, but such that nobody was willing to pay for.

We believe they did not manage to bring to market a commercially successful product because instead of developing one, they spent time and money on developing 'waste'. 'Waste' is defined as a product which may perfectly meet specification or demonstrate an engineering breakthrough, but still cannot be sold.

2. A Real Life Example

2. A Real Life Example

One of our clients developed an innovative product, which consisted of an array of electronic stethoscopes that passively monitor vibration energy from the lungs. The product enabled clinicians to monitor sites of airway obstruction without exposing the patient to radiation or invasive procedures. The company conducted a clinical study that demonstrated the accuracy of its system and received the FDA's clearance with the intended use of "monitoring lung sounds". At this point they approached us to help them develop their reimbursement strategy and implement it in the US.

After doing some homework we interviewed a couple of US payor representatives who immediately told us: "It is going to be a cold day in hell before we pay for this technology!" Had the product helped clinicians differentiate between Asthma and Chronic Obstructive Pulmonary Disease (COPD), they would consider it, but since they don't see what different clinical decisions could be made by "monitoring lung sounds", they won't pay for it. Such a product is an example of 'waste'.

You might also like

Nortech Systems' (NSYS) CEO Rich Wasielewski on Q2 2014 Results - Earnings .. — Seeking Alpha

This expertise is especially valuable for development stage and start-up medical device companies. These companies are looking to us as manufacturing partners, so they can better focus on research and development and marketing of their products.